Spando-NTT Representing a Series of Wear-Resistant Sleeves

The entire product range has been built by using extremely high-quality grades of polymers such as Polyethylene Terephthalate (PET), Polyamide 6 and 66 (PA6, PA66), Polyphenylene sulphide (PPS) and chemically modified Polyethylene (PE). To reach good balance of mechanical, physical and chemical performances, combinations of different polymers within a single product has been adopted. This allowed to enhance determined characteristics to overcome specific issues, such extreme mechanical stresses and chemical attacks contemporaneously.

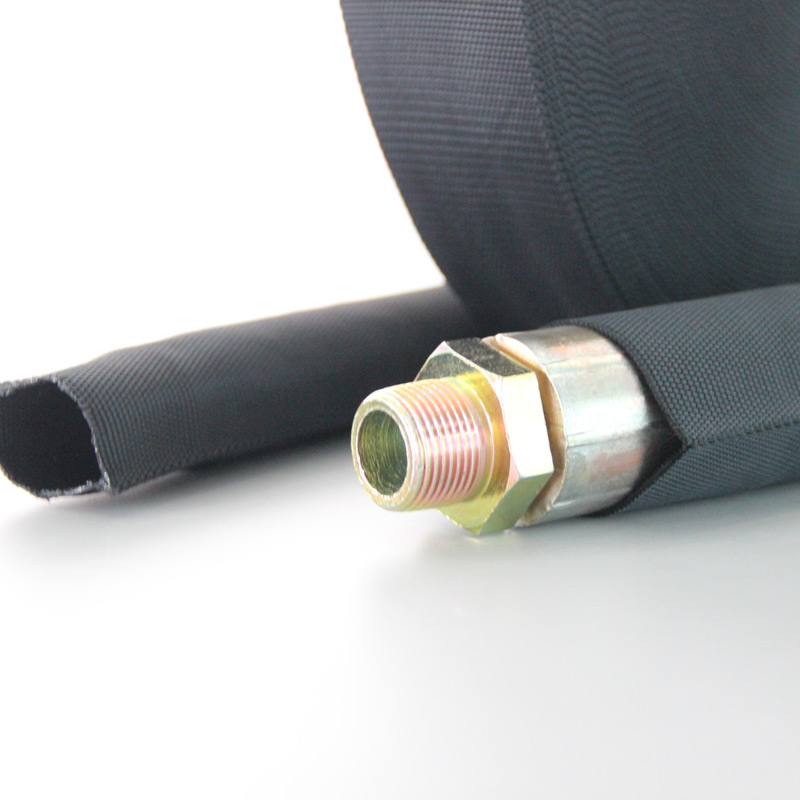

Spando-NTT® finds extensive application for the automotive industry, protecting high voltage cables, wire harnesses, rubber hoses or plastic tubes against abrasion, extreme high/low temperature stresses, mechanical damages and chemical attacks.

The sleeves are easily installed on components and can offer different expansion rates that allow fitting on bulky connectors. Depending on the level of required abrasion classes, sleeves with different surface coverage rate are offered. For standard application, a surface coverage of 75% is enough. However, we can offer expandable sleeves with superior coverage area up to 95%.

Spando-NTT® can be sent in bulky form, in reels or cut in predefined lengths. In the latter case, to avoid fraying end issues, different solutions are also offered. Depending on the demand, ends can be cut with hot blades or treated with a special antifray coating. The sleeve can be put on curved parts like rubber hoses or fluid tubes with any bending radius and still maintaining a clear-cut end.

All items are derived by using environmentally friendly raw materials and produced in respect and exceeding known standards in regard to low emission and safeguard of our planet. Especially important is the use of recycled materials, where allowed, to reduce overall energy consumption.