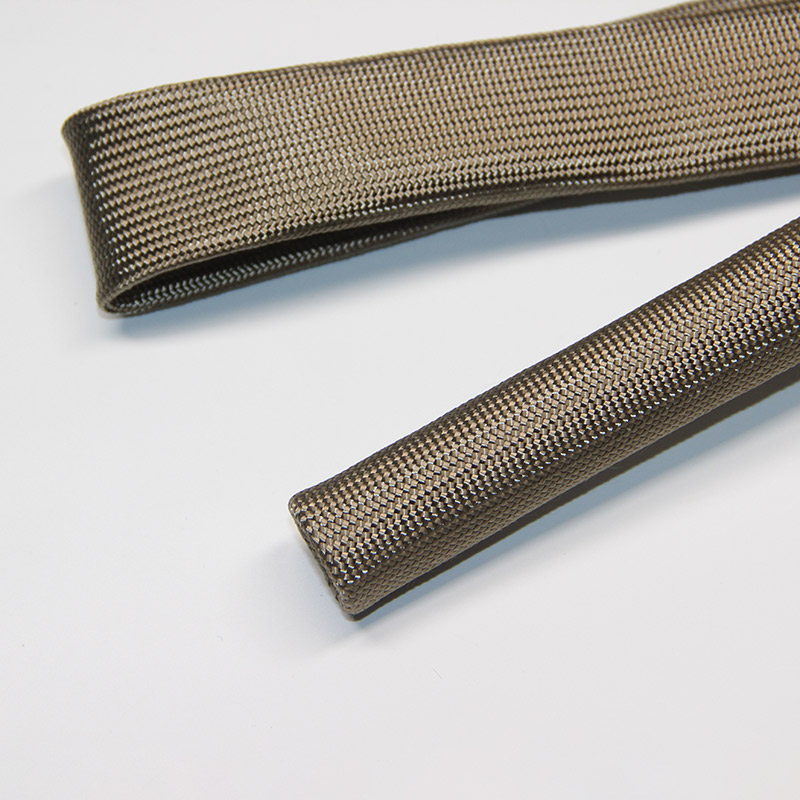

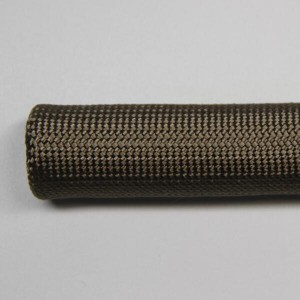

Basflex Formed by Intertwining Multiple Fibers Made of Basalt Filaments

Basalt sleeve

Material

Basalt fibers

Applications

Chemical protection sleeve

Mechanical protection sleeve

Construction

Braided

Dimensions

| Size | ID/ Nom. D | Max D |

| BSF- 6 | 6mm | 10mm |

| BSF- 8 | 8mm | 12mm |

| BSF- 10 | 10mm | 15mm |

| BSF- 12 | 12mm | 18mm |

| BSF- 14 | 14mm | 20mm |

| BSF- 18 | 18mm | 25mm |

| BSF- 20 | 20mm | 30mm |

product description

Basalt is a hard, dense volcanic rock that originated in the molten state. Today, this material is drawing interest among various applications such as the automotive sector, infrastructures and fire protection. Unlike glass, basalt fibers are naturally resistant to ultraviolet and high-energy electromagnetic radiation, maintain their properties in cold temperature, and provide better acid resistance. Furthermore, these products offer performance similar to S-2 glass fibers at a price point between S-2 glass and E-glass. With these advantages, basalt fiber products are emerging as a less-expensive alternative to carbon fiber for products in which the latter represents over-engineering.

With the above mentioned properties, a braided/knitted sleeve made out of basalt fibers have been developed with the trading name of Basflex. It is a product formed by intertwining multiple basalt fibers to create a closed radial structure that protects wire bundles, tubes and pipes, conduits etc. against heat, flame, chemical agents and mechanical stresses.

The Basflex braid has excellent heat and flame resistance. It is non-flammable, have no dripping behavior, and have no or very low smoke development. Compared to braids made of fiberglass, the Basflex have higher tensile modulus and higher impact resistance. When immersed in alkaline medium, the basalt fibers have 10 fold better weight loss performances compared with fiberglass. Additionally, Basflex has very low humidity absorption compared to glass fibers.

The chemical composition of basalt fibers is similar to that of glass fibers, but the production process of basalt fibers is more environmentally friendly and energy-saving than glass fibers. Once formed in a braided or knitted structure, the product generates very low smoke when exposed in a heat source. Since it does not contain hazardous chemical components (fully originated from natural materials) has much less impact to the environment and can be used in a longer perspective as a sustainable variant, providing great potential for use in various industries.

The product can be delivered in spools, festooned, or cut into pcs.